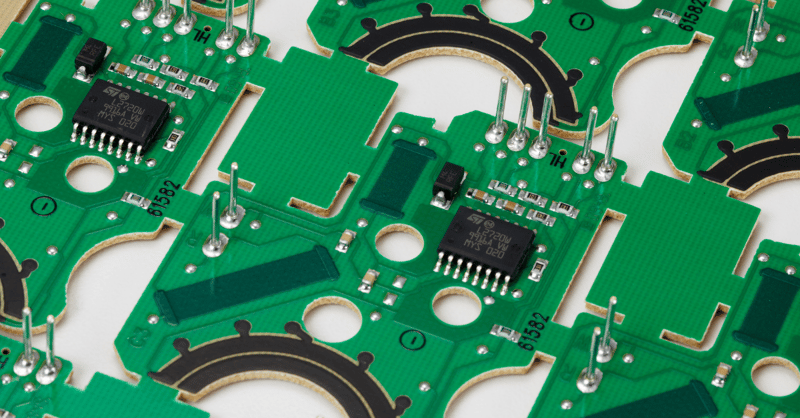

Automotive, computer, telecom, appliance, or industrial, when you’re building a PCB, you need high quality, highly reliable interconnect pins. Identifying a reliable supplier, one that can meet the project requirements on time and on budget, is essential to this process. Not all design parameters are clearly laid out so in addition to keeping in mind best practices it’s also important to explore custom solutions that cut through the pain points of PCB design.

Most would agree that a through-hole pin gives you a high-strength connection compared to regular SMT parts. Pin insertion is also a cost-effective and automatable means of delivering signal or power to your PCB. That's where the True Grip Pin comes into play.

Bead's True Grip Pin enables you to leverage the through-hole strength while still processing its insertion on the SMT line. This patented design offers a unique solution to the pain points of Pin-in-Paste or Through-Hole-Reflow technology.

Save on Processing and Material

Save on Processing and Material

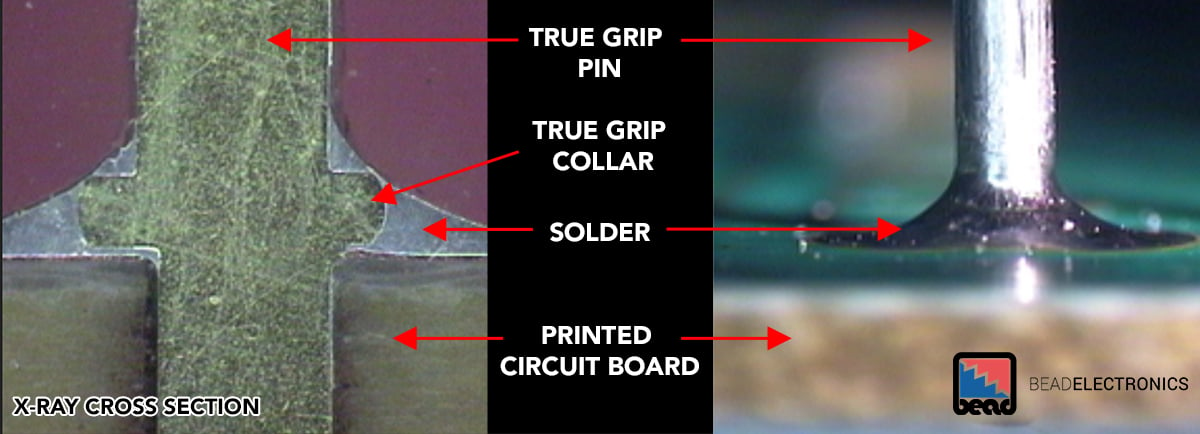

Pin-through-paste processing causes debris to be disbursed across the PCB creating contamination, defects, and scrap. During insertion, bending that can occur if pressure is applied to the pin tip. Material costs are through the roof.

Our pins are inserted by applying pressure to the flange, not the tip, so bent pins are eliminated.

Our True Grip pins require much less solder, meaning less debris, fewer defects, and less scrap. Less material used means we can keep our costs down and pass those savings onto our customers. This is a cross-section of our hybrid True Grip Pin soldered onto a PCB.

Many PCB manufacturers come to us from our competitors because of pin assembly defects and unreliable connections.

To learn more about the True Grip Pin, download this sale sheet.

Vision Inspection in Practice

We have several vision system cameras installed on our machines. The inspection data collected from the cameras provide traceability down to the day, hour, and minute of production and enable us to obtain precise measurements and reject any defective contact pins. This 100% Vision System inspection means our customers can have complete confidence in every single PCB pin we produce for them.

About Bead Electronics

Bead Electronics has experience working with PCB Design and Electrical Engineers. We work with you and your team on optimizing your packaging, pin insertion, and more. We're industry leaders in custom pins and pin assemblies for aerospace and military, healthcare, automotive, and communications devices. Click here to speak to a connector pin specialist today.