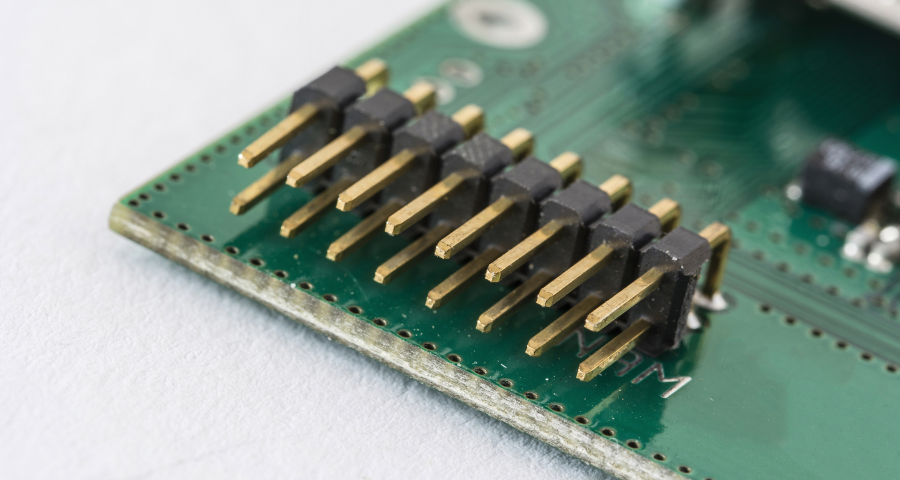

Connectors are critical for applications in a wide range of industries. Devices are becoming smaller. Many manufacturers take a modular design approach to bring products to market faster.

The increasing number of printed circuit boards requires more and more connectors. Standard connectors may not meet the requirements. Custom connectors let you design a connector that fits your exact specifications.

Learn more about custom connectors and what the design process involves.

When to Consider Custom Connectors

Custom connectors are beneficial in many circumstances. They can help you launch a new product more successfully. You can scale production more efficiently.

A new custom connector can help you meet product validation dates. You can avoid long lead times.

Common reasons a custom connector instead of a standard connector may be the best option include:

- Mechanical and electrical/electronic requirements are not met with standard connectors

- Needing extra protection from extreme environmental conditions

- Failing to meet creepage and clearance standards

- Failing to meet testing standards

- Needing to align PC board contacts with your product's unique layout

- Facing long lead times or the lack of specialized parts

Custom connector pins can help you change existing products or create new ones.

Modifications vs Completely Customized Connectors

You may be cautious about using custom connectors if you're in an industry like aerospace. The process for approvals and the need to meet stringent requirements can be a deterrent.

Custom connectors can use the design of Qualified Products List parts as a baseline. This provides assurance that the customized part will meet reliability and quality specifications.

Modifications to an existing design can reduce the cost of development. A modified product may have fewer prototyping and testing requirements. The approval may be easier than for a new design.

Consider the Application for Custom Connectors

The application is a primary consideration for custom connector design. The application helps determine all elements of a new custom connector.

Some applications require a more complex configuration than others. For example, a GPS unit probably needs a multi-pin connector. A simpler application may only need a wire-to-wire crimp connector.

How Often Will the Connector Be Mated and Unmated?

Connectors fall into one of several basic categories. The primary function of the connector helps determine which type you should choose.

Permanent

Permanent connectors stay mated for the life of a product. They won't undergo repeated plugging and unplugging.

Semi-Permanent

The design of semi-permanent connectors allows access for disconnection or replacement when necessary. You can access a semi-permanent connector when servicing or replacing a part.

Active

Active connectors need to withstand repeated plugging and unplugging. They need to be wear resistant.

Disposable

Disposable connectors have specific uses in applications like medical devices. Disposable connectors have a short or one-time use. Users dispose of them instead of attempting to sterilize them.

What Is the Service Environment?

The service environment of the connector helps determine some of its design considerations. Factors to consider include:

- Operating temperature

- Placement on the component

- Exposure to substances like grease, chemicals, water, dirt, or dust

Vibration

For example, shielding can protect against unwanted electromagnetic interference radiation.

Connectors may need shielding because of their location on the component.

In applications with high mechanical stresses, the connector may need better rigidity. Bosses, threaded inserts, and pin serrations can help with retention.

Material Considerations

Many options for connector materials are available. The materials affect the weight, cost, and reliability of the component. Custom connectors give you the choice of materials.

You can select the base metal, contact plating, and the shell. Common base metals are:

- Steel

- Copper

- Brass

- Aluminum

Stainless steel is the best choice for a medical environment with frequent sterilization. Aluminum alloys are lightweight and can withstand harsh environments. Brass connectors can handle excessive wear.

Metals for contact plating include:

- Tin

- Gold

- Nickel

- Palladium nickel

Gold has excellent electrical and thermal properties. Nickel is a good choice for high-temperature applications. Palladium nickel is very durable with good electrical and thermal properties.

Electrical Requirements

The voltage and current requirements for your application determine design details like:

- Number of contacts

- Contact size

- Contact spacing

- Wire size

- Insulation material

For example, you'll need a stronger insulating material if high voltages are present. Wide pin spacing is another way to handle high voltages.

High-power signals like ground connections may require several pins connected together. You can also use dedicated pins for power, ground, and signal traces.

High-current applications can create heat from resistance in the pins. This can require extra cooling, which needs more space.

Space Requirements

Many connector applications have strict space requirements. Miniaturized connector solutions may be necessary. Space considerations include:

- A large enough connector to handle the required current

- Enough space for the necessary contacts or extra connectors

- Space for adequate cooling and ventilation elements

Nesting or ganged arrangements are possible. Combined functionalities with fewer interfaces can help reduce the space a connector needs.

Termination Style

The connector termination attaches the connector to individual conductors. The conductors can be discrete wires or jacketed cables. PCB connector terminations include:

- Through-hole

- Surface mount

- Pin-in-paste or through-hole-reflow

- Press-fit

The termination style affects how well the connector is sealed. It also determines its mechanical strength.

Choosing a Custom Connector Manufacturer

Many factors contribute to the design of custom connectors. The service environment of the connector determines many aspects of custom connector design. The right design choices help ensure the connector performs reliably.

Bead Electronics provides custom, quick, and cost-effective pin manufacturing to provide for your custom connectors.

At Bead we're dedicated to meeting the specific needs of your project. We deliver quality products on time that meet and exceed our customers' requirements.