Many of the connectors that have been used over the years were developed in Bell Labs by Paul Neill, at Amphenol by Carl Concelman, or both. But, it was Octavio Salati who filed his patent in 1945 for the BNC connector. The humble BNC connector went on to influence RF, television, satellite, and microwave connector solutions for generations.

Even today, new variations of the connector are being iterated and custom connector pins are being used in countless complex designs to facilitate stronger, lasting connections between components.

Want to know more about connectors in everything from satellites to PA systems? Need to know how contact pins, Information technology (IT), and communication technology continue to change?

The truth is that almost all communication devices and industries have a need for specialized and durable connectors.

Examples of communication devices in the communication industry that need special connectors are:

Examples of communication devices in the communication industry that need special connectors are:

- Satellites

- Microwave and RF applications

- Cell phone towers

- Wireless LAN

- Video broadcast and production equipment

- Amateur radio

- Aerospace communications

Spaceflight, defense, and aerospace applications for RF and microwave connectors are very high. They need to be low in weight, high in ruggedness, and 100% dependable with little maintenance.

To read more about plating considerations for custom connectors, check out our free whitepaper.

Connectors in Mil-Spec Communication

To do all this, there are usually specific needs that are met by special plugs and sockets that meet a mil-spec or military standard specification, such as MIL-STD-348 or MIL-STD-202.

This comes in the form of MIL-C-5015 or MIL-C-38999 or other connector specifications. Those two specifications mentioned cover environment-resistant cylindrical connectors, usually in high density.

These are often even space-grade telecom connectors with high signal and power requirements that need to be met. Sometimes that includes special material needs.

Connectors in Microwave and RF Applications

RF and microwave connectors have several features they need to live up to, depending on the application.

If they're exposed to the environment or harsh industrial conditions they may need moisture or oil resistance. To match the needs of those conditions, connector engineers use seals and gaskets to protect the connector.

Hermetically sealed connectors have fewer demands on them but need to have protection against gases and air in general. This reduces corrosion but doesn't prevent external moisture ingress.

Hospital-grade connections and connectors for medical applications have unique challenges to overcome, due to health and safety needs. They need to withstand cleaning with chemicals, accidental plug disengagement, and higher impact and shock ratings.

Another feature to look for in industrial applications is an environmentally resistant connector. These connectors get tested for hazardous chemical conditions and environments, including harsh sulfuric acids.

Impedance

Impedance in RF and microwave connectors are usually 50 ohms or 75 ohms (Ω). Most connectors are either 50Ω or 75Ω and it's not ideal or possible to mix them most of the time.

50Ω connectors on 75Ω cables should only be used for less than 500MHz, or the low end of UHF. 75Ω connectors cost more, so it can be done in a pinch. However, 75Ω cables are more valuable than 50Ω cables, so it's better to keep them matched.

The connector and cable should be the same diameter to reduce signal reflections.

Signal reflections greatly reduce performance. Signal reflections increase or decrease along with frequency. The smaller the connector, the better performance at a higher frequency. The larger the connector, the worse it will perform.

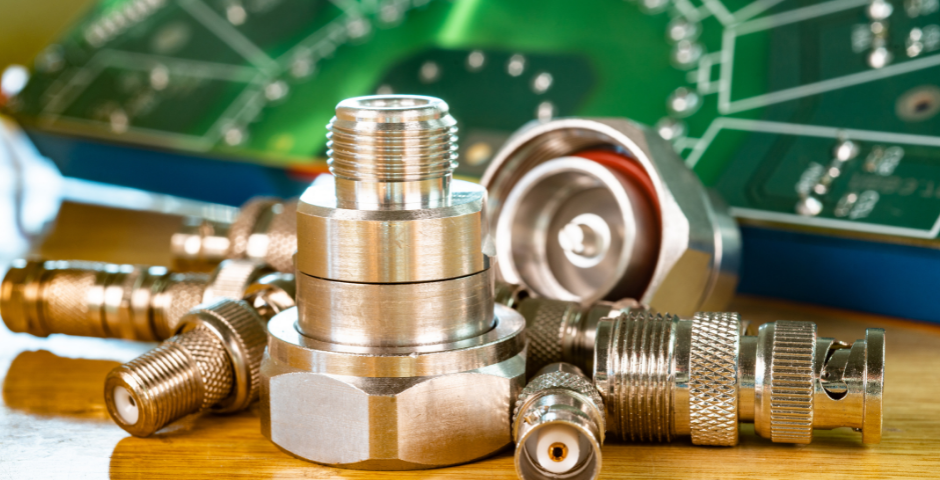

Common RF and Microwave Connectors

Common connectors include some connectors going back to the 1960s, 1940s, or even 1920s. Despite how long they've been in use, they are reliable connections that provide high performance in most RF and microwave applications.

Some common connectors are:

- BNC

- TNC

- SMA

- SMB

- SSMB

- DIN 1.0/2.3 (SDI or UHF)

- Twinax

- Type N

- 7-16

- MCX (Miniature coaxial)

- MMCX (Micro-miniature coaxial)

For GPS, WLAN, and Cell base stations, MMCX and MCX provide excellent solutions.

SSMB connectors are 30% miniaturized versions of already-small SMB connectors, developed in 1995. They're fairly durable and popularly used in defense, communications, and telecom.

SMB connectors, though, fall under MIL-C-39012 standards and have a long history of use in telecommunications, instrumentation, GPS, LAN/WAN, Antennas, cellular base stations, and radio boards.

Common plating options for RF and microwave connectors are gold, nickel, and tin-lead.

Communication Connector Specifications

There are many parts of connectors and connections that need to adhere to standards. For example:

- Cable size

- Impedance Frequency range

- Working voltage

- Voltage standing wave ratio, or VSWR

- Insertion loss

- Operating temperature

- Power

High-power applications demand larger diameter connectors, but higher power means more noise.

Signal strength is impacted by insertion losses. This means the loss in dB of total RF power transmission.

In fiber optics, it's the loss of energy as photons pass from one material and transition into another. A similar phenomenon occurs when electricity passes from one device into another.

Some of the most important factors of deciding on a cable and connector are the range and frequency of those parts, as well as the need to accommodate a strong and lasting connection. Bayonet-style mounts or push-on connectors are best for frequencies below 6Ghz. Low-noise high-performance applications need a tighter connection, so threaded connectors work best.

Connector Geometry and Gender

Connectors come in two genders—male and female. RF male connectors usually are the portable end, where the RF female connector is generally on the device.

Male connectors are also called headers, plugs, or free connectors. This is because they are the one being moved around. Female connectors are also called jacks.

Female connectors are usually mounted on device racks, representing the "hot" end. Hot connections have power, signal, or both going through them.

Male or female connectors can either be straight connectors or right-angled. In the case of a plastic housing, they're likely overmolded. Overmolding is when the pins are in place during injection molding.

If the connector is made of metal, the connector is either crimped or soldered into place.

Knowing Which Electrical Connectors to Use For Communication Applications

There's no way for anyone but you to choose the best connector for your communication applications. With several to choose from, the frequency range of your cabling and connectors is the best first place to start.

From there, make sure you can fulfill ruggedness, environmental requirements, and space constraints. If it's an aerospace or spaceflight application, you also have residual magnetism, weight, and space requirements beyond the norm.

Once your application's requirements have been defined, it's time to identify a solid partner to facilitate the transition from design to fabrication. Work with a high-quality connector pins manufacturer to move your project into production.

About Bead Electronics

Bead Electronics, is a global manufacturer of electronic connector pins and has been manufacturing in Connecticut for over 100 years. The award-winning company carries over 500 patents and is best known for inventing its manufacturing process called swaging. This process is a high-speed, virtually scrap-less, cold-forming process capable of producing a wide size range of metal electronic components that are consistent and cost-effective. The family-owned business is led by its fifth generation. Click here to speak to a connector pin specialist today.