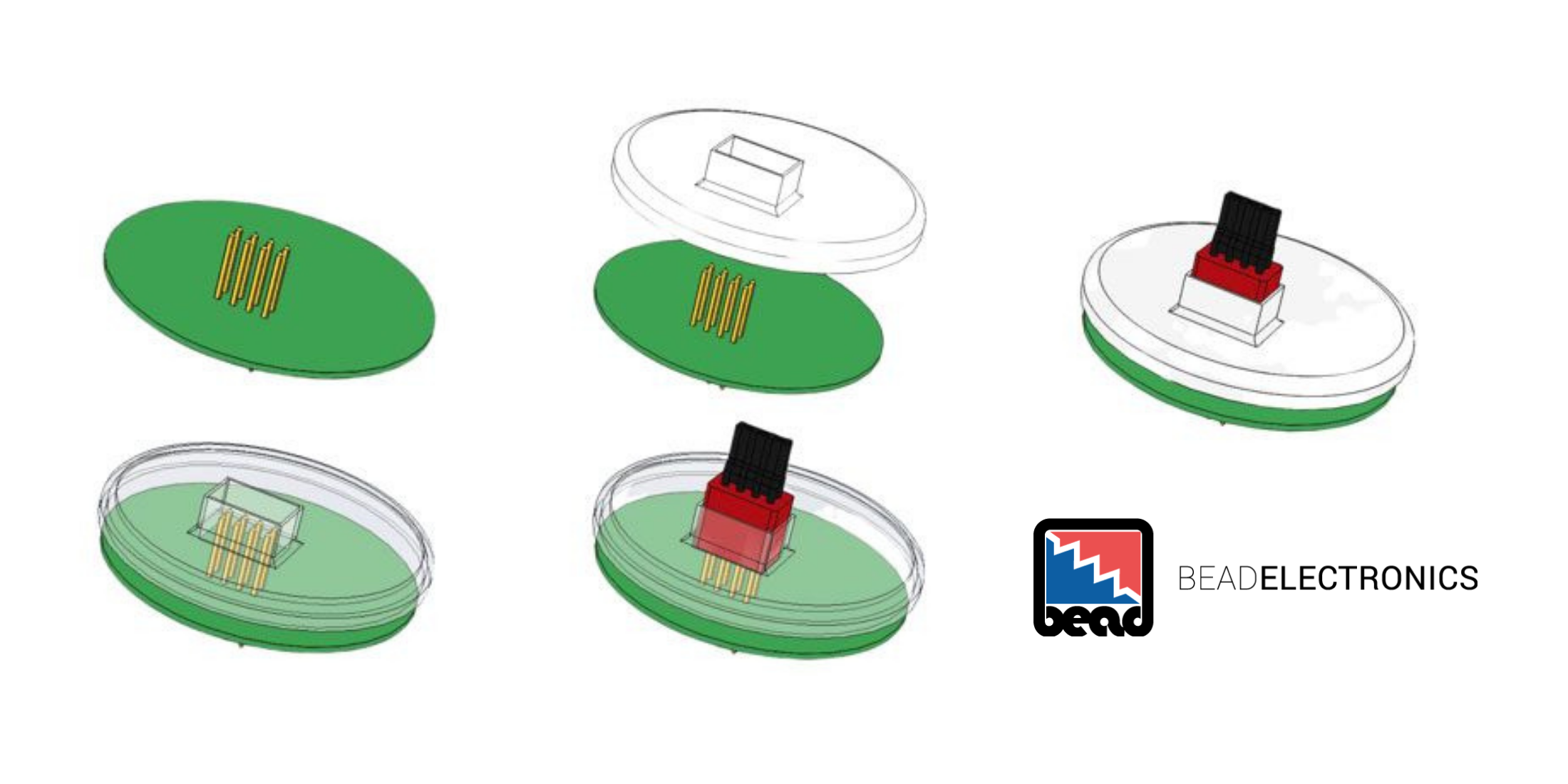

Molds have revolutionized manufacturing - enabling suppliers to mass-produce identical parts in rapid succession. Injection molding, the process of injecting molten plastic into a mold to create a component, is widely used in the automotive, aerospace, industrial, and medical industries. Injection molding can be further broken down into two types: insert molding and overmolding.

Read More