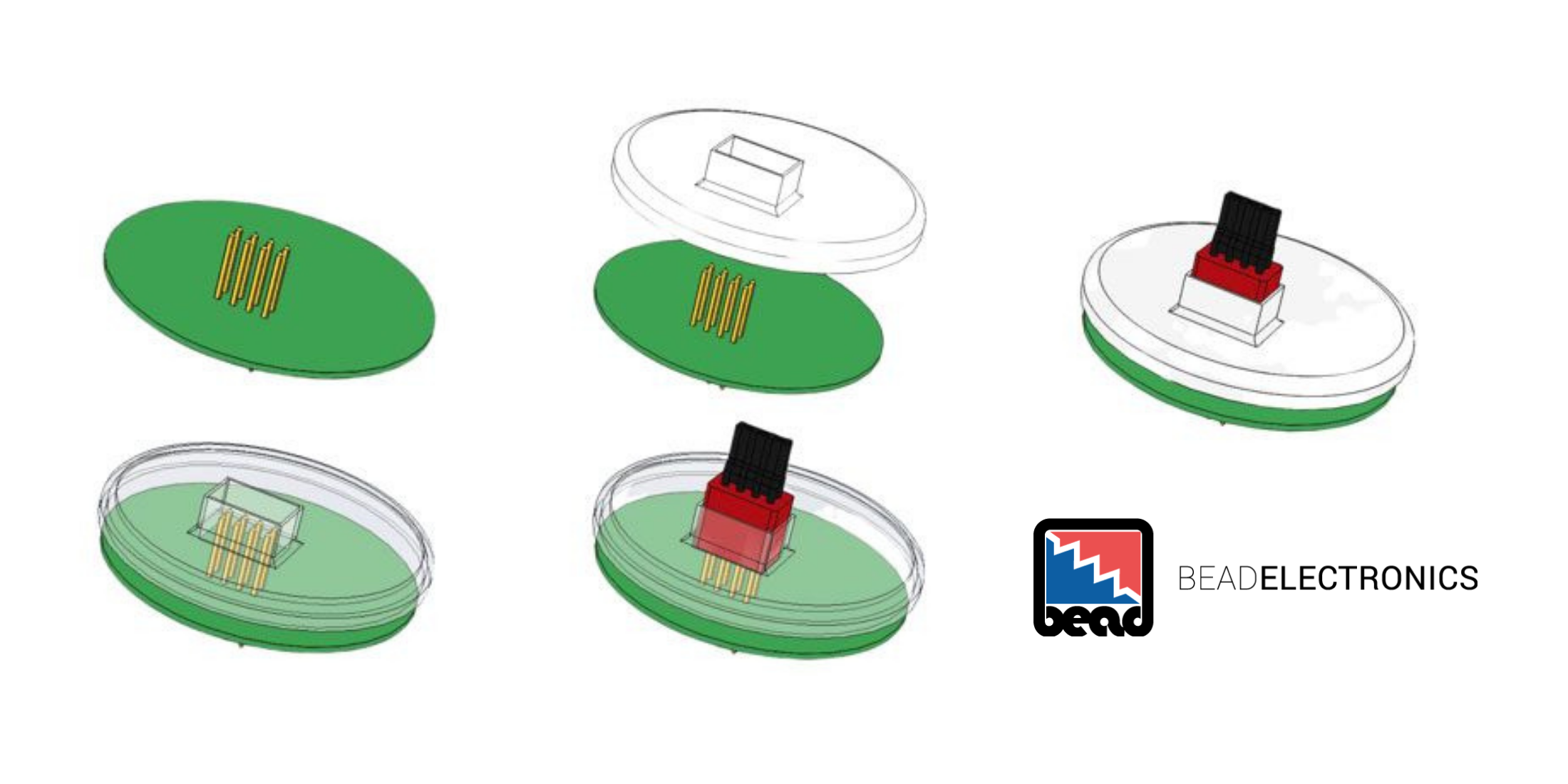

Imagine having to perform surgery when your tools don't feel right in your hands. With an improper grip or a flawed tool, the outcome of your procedure can be compromised. Any tool for any job needs to have that ergonomic benefit to optimize the outcome and enhance performance.

Read More