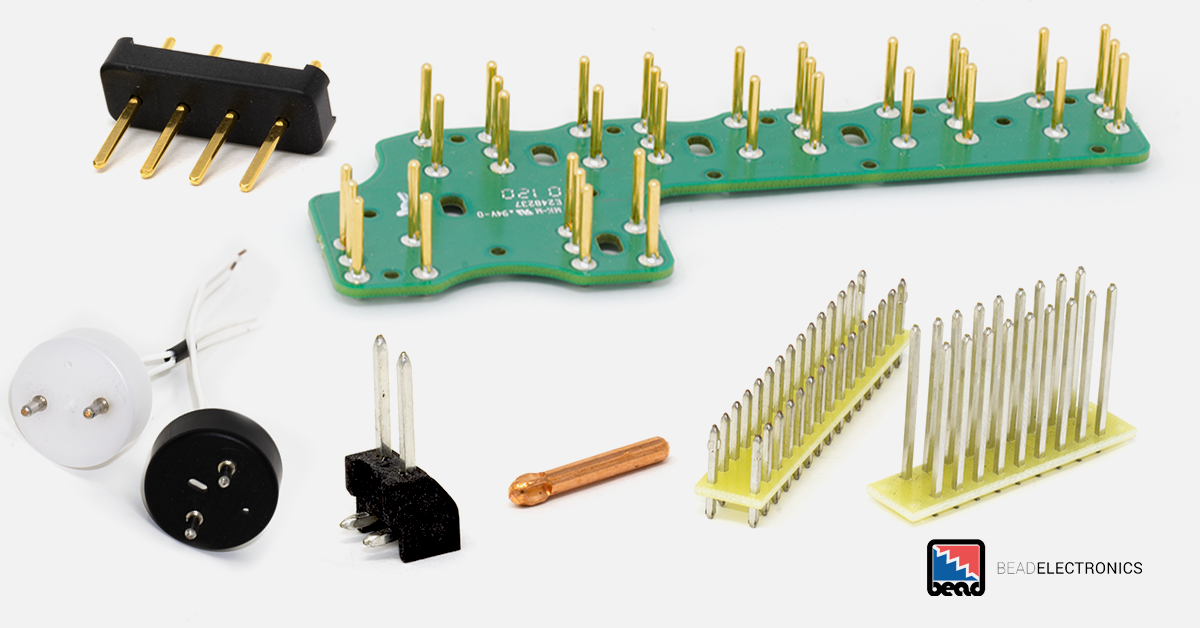

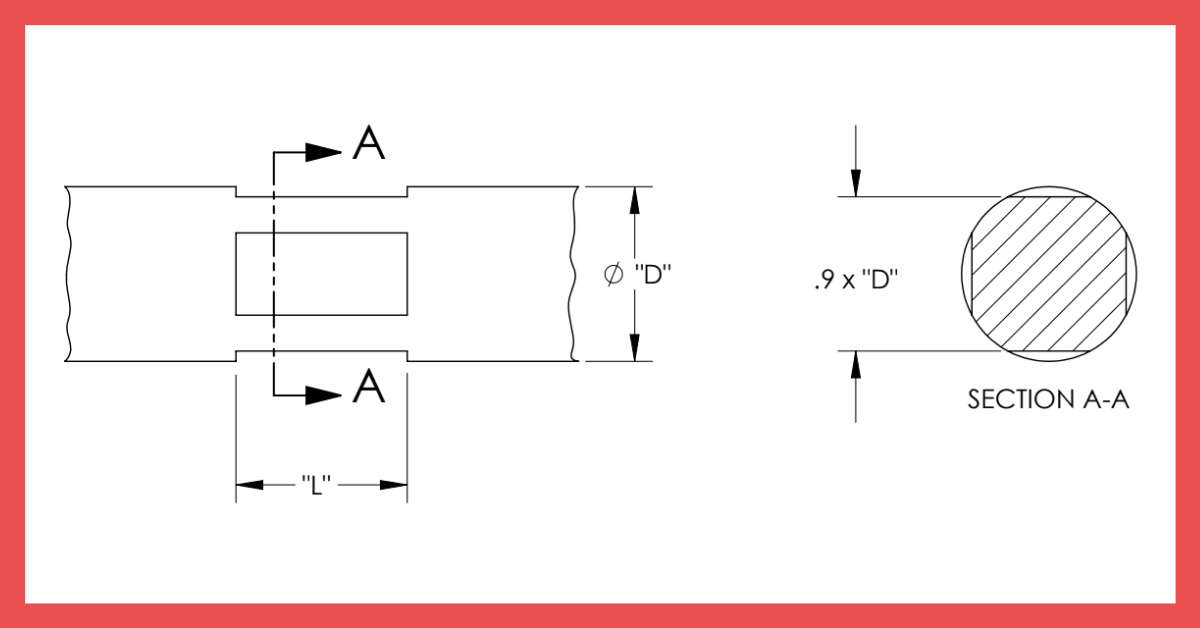

At Bead Electronics, we are constantly evolving to answer the intricate questions of our clients and assist them in understanding the diverse applications and potential of hollow bead pins. Recently, we received a thoughtful query about the nature of these pins and how they could be secured within an assembly.

Read More