When it comes to manufacturing products that people use every day, durability is key. Consumers want products that are innovative and easy to use. They also want the things that they invest in to have longevity. Manufacturers have an obligation to create high-quality products and to accomplish this, they rely on components customized for their applications. Even the smallest part, like electrical connectors, are customized to boost both profits and customer satisfaction.

Countless everyday products rely on these internal connections to function. We've compiled this list of unexpected products that rely on interconnect pins. By the end of this article, you'll know how to take full advantage of custom connectors for your own applications. Read on to find out more about where you could be using our durable interconnect pins.

Custom Connector Pins in Smoke Alarms

Fire alarms and smoke detectors are life-saving pieces of technology. As a permanent fixture in people's households, they have to last a long time and be guaranteed to work to their full potential. For that reason, manufacturers rely on customized, high-quality connector pins, which are a vital component of this incredibly important everyday item.

Custom connector pins in smoke alarms allow for a cost-effective solution and a long-lasting product. By leveraging pin insertion and plastic design, the overall cost of production is reduced while the structural integrity of the product remains intact. This is a primary use of high-quality connector pins. This kind of reliability is just one of the benefits of working with an interconnect pin manufacturer like Bead Electronics.

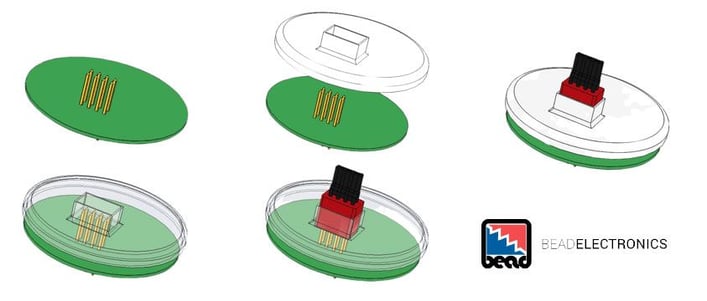

|

This rendering demonstrates how to leverage end-to-end pins to facilitate a custom, mated pair in a practical application like a smoke alarm. |

PA Systems Use Connector Pins

PA systems for communication and broadcast applications rely on connector pins to function. They are usually powered by crimped connections or IDC connections.

These systems are used everywhere, from supermarkets and schools to warehouses and workplaces. They are often an important part of the running of an establishment and need to be steadfast in their reliability.

PA systems are also another product that can always benefit from the use of custom interconnect pins in manufacture.

Finding the ideal pin for a design allows for a simplified and streamlined manufacturing and assembly process. It makes the product both sturdy and simple for the consumer to handle, own, and eventually repair.

Using custom connectors in PA systems and other communication applications means you can provide a product made of serviceable and testable parts. It is a foolproof way of ensuring high-quality results and, ultimately, happy consumers.

Interconnect Pins for Equipment Controls

These products exist in every home, hospital, vehicle, office, and school in some form or another. Interconnect pins are used to work controls on all sorts of equipment and machinery.

Being able to work equipment can have a significant impact on someone's productivity. Consumers need to be able to use their products, so longevity is an important part of making equipment controls. The connector pins used inside a set of controls can be optimized by professionals who make custom interconnect pins.

Both consumer and manufacturer benefit from working with an interconnect pin manufacturer.

The process of swaging, used by Bead Electronics to make our connector pins, produces many components at a time. This, and the nature of our products, saves time and labor in the manufacturing process for your product.

No molding or soldering is required when their interconnect pins are used in a piece of tech. This saves on multiple expenses and is a key part of why using custom pins makes the product that reaches the consumer easy to service and fix.

A High-Quality Interconnect Pins Manufacturer for Ventilators

Though consumers might not realize it, ventilators are a key part of countless everyday products. This is why they should be designed for manufacture and use custom interconnect pins that will make them more durable.

Coil winded valves enable ventilators to function, using connector pins to get power. Being such a vital part of many everyday items, ventilators must be both reliable and reparable.

Custom interconnect pins could make any ventilator so—and at a lower cost to manufacturers.

We cannot overstate the benefits of offering a durable and easily fixable product to customers. A good interconnect pin manufacturer can work with you to find the perfect interconnect pins for your product.

Interconnect Products Are Everywhere

When it comes to most mass-produced technology, anywhere a signal or power is present, some form of connector pin will probably be involved in a product. There are countless everyday items that use interconnect pins. Examples include printed circuit boards (PCBs) or overmolded connectors.

Mirror dimmers and reflection control use connector pins to function. In the automotive industry, many types of sensors need them in order to work. If there is an item containing a small motor, it uses pins to keep the product fulfilling its function.

All of these products can be made using custom interconnect pins.

Using custom pins saves time and money during the process of making your item. It ensures durability and reliability for the customer. It even reduces the difficulties that can come from eventual wear and tear. Simply put, it's the ideal way to optimize a product.

Consult the Experts Today

Professionals at Bead Electronics have been developing custom interconnect technology for over 100 years.

We know how to make a great component, having more than 500 patents and a traditional, tested method of manufacture. There's no better high-quality interconnect pins manufacturer to work with.

If you're producing an everyday item, you can work with us and reap the rewards of using custom connector pins. Get in touch today for a free quote and revolutionize the manufacture of your everyday products.