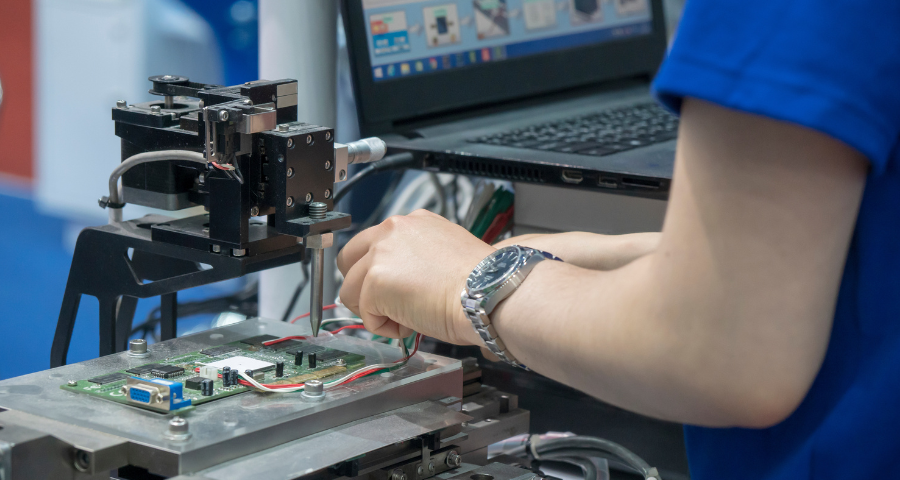

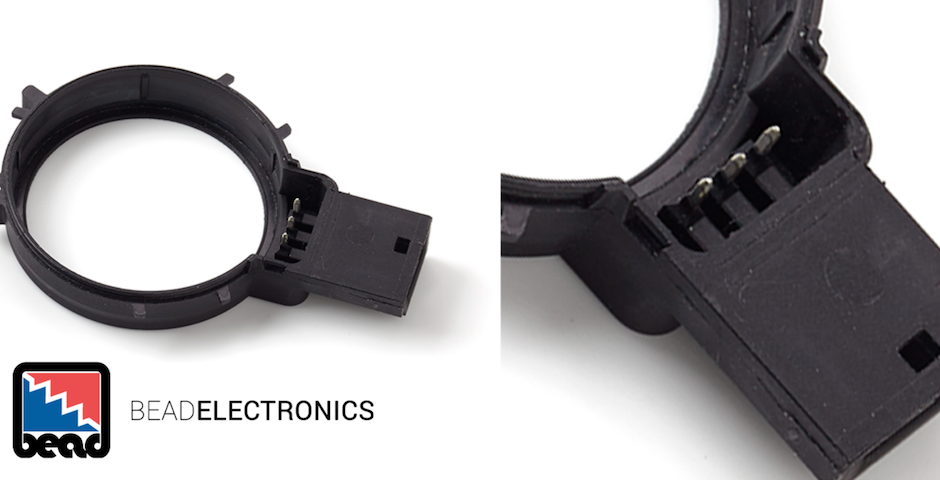

Major, direct impacts on manufacturing costs fall into a few common factors like supply and demand, testing, certifications, or labor. The one that we're going to talk about falls under manufacturing processes— specifically pre-plated projects. Whether pre-plated projects are your thing, or post-plated projects, the order of operations in industrial plating matters and affects your bottom line.

Read More